4 Head Double Station Blow Molding Machine 1000 Bph 5l Automatic Bottle

-

High Light

4 head Double Station Blow Molding Machine

,1000 bph Double Station Blow Molding Machine

,5l automatic bottle blowing machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity5L

-

Product1L Highly Plastic Barrier Layer Bottle

-

Machine TypeU Series

-

Layer4 Layers

-

Die Head4 Heads

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBU-65

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

4 Head Double Station Blow Molding Machine 1000 Bph 5l Automatic Bottle

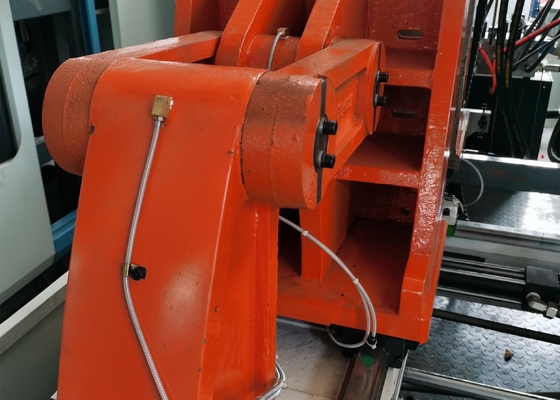

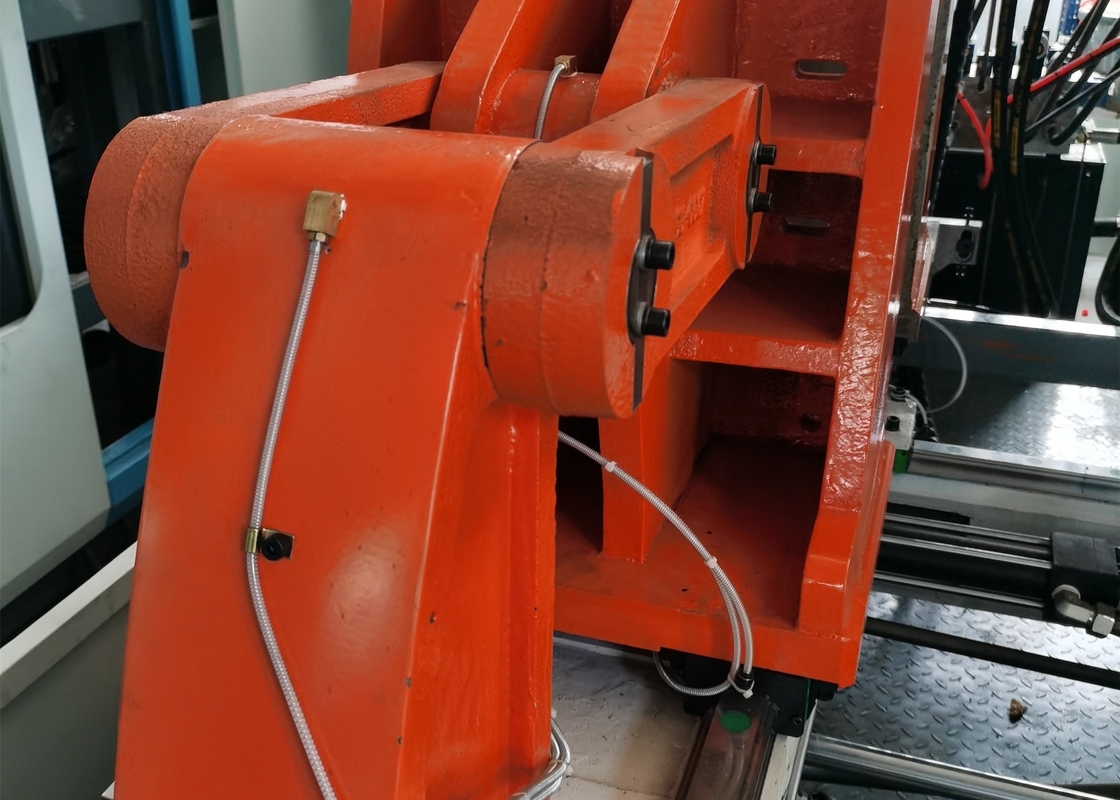

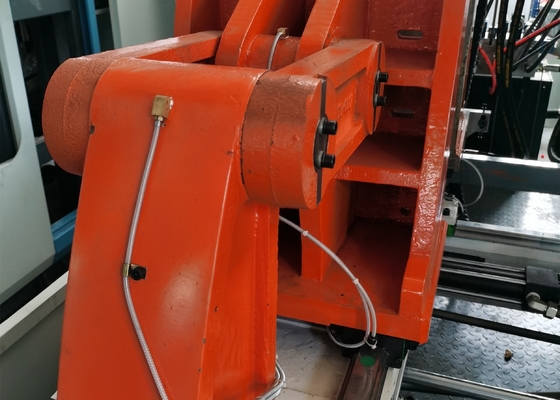

U series High Speed 4 Layer Double Station 4 Die head Blow Molding Machine for 1L highly Plastic Barrier Layer Bottle

SLBU series:

1: this machine is suitable for the production of 200ML -5L plastic hollow products.

2: Pressure pointer, when the pressure pointer on the pressure gauge points to 100 bar, stop the rotation and lock the screw on the upper nut to prevent the screw from loosening, so that the maximum pressure of the whole system is always 100 bar.The pump's hydraulic system is also equipped with a large pump pilot unloading valve. When the screws for adjusting the oil return pressure on the unloading valve are all loosened, the large pump unloading valve has the largest oil return, and the large pump system has the lowest pressure. In order to increase the speed of opening and closing the mold and the mold shifting action, the unloading valve can be adjusted. The amount of oil returned and the pressure are increased, but the maximum is not allowed to exceed 55 bar.

| SPECIFICATION | SLBU-65 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4000x2300x2200 |

| TOTAL WEIGHT | TON | 6.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-520 |

| PLATEN SIZE(WxH) | MM | 400x430 |

| MAX MOULD SIZE(WxH) | MM | 460x430 |

| MOLD THICKNESS | MM | 255-280 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 15 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 180 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 50 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 18 |

![]()

![]()